MANUFACTURING PARTNERS:

MANUFACTURING PARTNERS:

deuter sets store in long-term partnerships

based on trust and mutual respect. Establishing good working relationships that are equitable is important to us. deuter consciously abstains from supplier hopping (frequently changing suppliers to gain more favorable prices). Because that’s how we can build mutual trust and closer ties with our partners. Every employee – whether they’re in Asia, USA, or Europe – is a highly valued member of the deuter family. We work together with our partners in an open, honest, and constructive way.

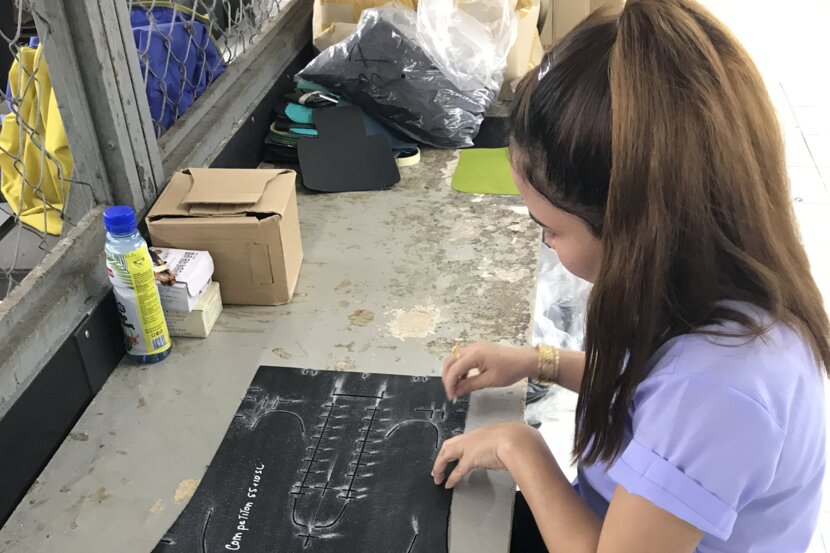

Duke, in Vietnam, has been making our entire backpack collection to the highest standards since 1991

Duke – our backpack partner

Duke, in Vietnam, has been making our entire backpack collection to the highest standards since 1991. Duke manufactures exclusively for deuter, and deuter in turn pledges to have all its backpacks made by Duke. The site is responsible for 90% of all deuter products.

What started out with just 35 sewing machines and 50 employees, has now grown into two highly specialized backpack factories in Vietnam, with around 4,000 employees exclusively making deuter backpacks and accessories. And today, Duke is not just responsible for production, but also for logistics in all our distribution countries.

For two generations now, deuter has enjoyed a close relationship with the Oh family and Duke, based on mutual trust and friendship. Over the last 30 years+, Duke has developed a high level of expertise as a manufacturer, supplier, logistician, and partner to deuter. For instance, Duke has a special CSR team at its headquarters and production sites that ranks highly within the management hierarchy and is therefore able to affect change or address issues effectively together with senior management.

AND WE COOPERATE WITH OUR SLEEPING BAG PRODUCER BELLMART IN CHINA SINCE 2004 AND IN MYANMAR SINCE 2015.

Bellmart – our sleeping bag partner

In 2004, deuter teamed up with Bellmart to develop down and synthetic sleeping bags together at its factory in Xiamen, China. Initially, this is where our entire sleeping bag range was made.

In 2015, the production of synthetic fill sleeping bags was moved to Bellmart’s production site in Myanmar, leaving only down sleeping bags in Xiamen.

Bellmart is a bluesign® System partner and is therefore regularly inspected by bluesign® advisors to ensure that good OHS (Occupational Health & Safety) and environmental standards are being upheld. Its Xiamen factory is also certified according to the RDS (Responsible Down Standard).

We maintain regular communication with our partners and carry out joint auditing and training measures. Audits are scheduled at intervals of 3 years at most, to get a clear understanding of the situation in each factory. Audit reports are discussed at regular meetings (at least twice yearly) between senior management teams from deuter and our suppliers. The deuter CSR team then follows up on any corrective action plans which arise from these audits with emails, Skype or video conferencing calls, and in-country site visits.

List of Sourcing Countries

At deuter, the supply chain is divided into two stages: Producers (manufacturers, Stage 1) and Material Suppliers (Stage 2 and deeper). We maintain a direct (contractual) business relationship with the producers, while also playing a significant role in selecting material suppliers. The producers utilize the materials to manufacture the final deuter products.

We share our Promise Policy with all our suppliers, who are obligated to adhere to the standards set forth within it. Our policy defines deuter's requirements and recommendations regarding social and environmental sustainability aspects to all production partners, aimed at mitigating the risk of harmful practices.

Through close collaboration with bluesign® and the Fair Wear Foundation, as well as utilizing the HIGG Index, we have gained comprehensive knowledge about the current state, improvement opportunities, and development possibilities of many of our producers and material suppliers. These partnerships allow us to have a deep understanding of working conditions and sustainability aspects within our supply chain.

To ensure transparency, we provide information about the countries and regions where our products are manufactured, as well as the materials used.